Drafter Drawer Style Paper Box

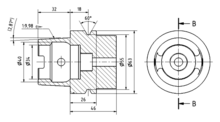

Technical drawing of a die tool produced by CAD (in Russian).

Copying technical drawings in 1973

Technical drawing, drafting or drawing, is the act and subject field of composing drawings that visually communicate how something functions or is constructed.

Technical drawing is essential for communicating ideas in industry and engineering. To make the drawings easier to sympathise, people utilize familiar symbols, perspectives, units of measurement, notation systems, visual styles, and page layout. Together, such conventions constitute a visual language and assist to ensure that the drawing is unambiguous and relatively easy to sympathize. Many of the symbols and principles of technical cartoon are codified in an international standard called ISO 128.

The need for precise communication in the preparation of a functional certificate distinguishes technical drawing from the expressive drawing of the visual arts. Artistic drawings are subjectively interpreted; their meanings are multiply determined. Technical drawings are understood to have one intended meaning.[1]

A drafter, draftsperson, or draughtsman is a person who makes a drawing (technical or expressive). A professional drafter who makes technical drawings is sometimes called a drafting technician.

Methods [edit]

Sketching [edit]

Sketch for a authorities edifice

A sketch is a rapidly due east. xecuted, freehand drawing that is normally not intended as a finished piece of work. In full general, sketching is a quick manner to tape an idea for subsequently utilise. Builder's sketches primarily serve as a way to try out dissimilar ideas and establish a composition before a more than finished work, especially when the finished work is expensive and time-consuming.

Architectural sketches, for example, are a kind of diagrams.[ii] These sketches, like metaphors, are used by architects as a ways of advice in aiding design collaboration. This tool helps architects to abstract attributes of hypothetical provisional blueprint solutions and summarize their complex patterns, hereby enhancing the design process.[2]

Manual or past instrument [edit]

One-time-fashioned technical cartoon instruments

Stencils for lettering technical drawings to DIN standards

The basic drafting procedure is to place a piece of paper (or other material) on a smooth surface with right-angle corners and straight sides—typically a drawing lath. A sliding straightedge known every bit a T-square is then placed on ane of the sides, allowing it to be slid beyond the side of the table, and over the surface of the newspaper.

"Parallel lines" tin can be drawn simply by moving the T-foursquare and running a pencil or technical pen along the T-square's edge. The T-square is used to hold other devices such every bit set squares or triangles. In this case, the drafter places one or more than triangles of known angles on the T-square—which is itself at correct angles to the border of the table—and tin and then draw lines at any chosen bending to others on the folio. Modernistic drafting tables come equipped with a drafting car that is supported on both sides of the table to slide over a large piece of paper. Because information technology is secured on both sides, lines drawn along the edge are guaranteed to be parallel.[3]

In addition, the drafter uses several technical drawing tools to describe curves and circles. Primary among these are the compasses, used for drawing uncomplicated arcs and circles, and the French curve, for drawing curves. A spline is a safe coated articulated metal that can be manually bent to virtually curves.

Drafting templates assist the drafter with creating recurring objects in a drawing without having to reproduce the object from scratch every time. This is particularly useful when using common symbols; i.eastward. in the context of stagecraft, a lighting designer volition draw from the USITT standard library of lighting fixture symbols to bespeak the position of a common fixture beyond multiple positions. Templates are sold commercially by a number of vendors, usually customized to a specific chore, simply it is besides not uncommon for a drafter to create his own templates.

This basic drafting system requires an accurate tabular array and constant attending to the positioning of the tools. A common error is to let the triangles to button the peak of the T-square down slightly, thereby throwing off all angles. Fifty-fifty tasks equally elementary as drawing 2 angled lines meeting at a point require a number of moves of the T-square and triangles, and in general, drafting can exist a time-consuming process.

A solution to these problems was the introduction of the mechanical "drafting machine", an application of the pantograph (sometimes referred to incorrectly as a "pentagraph" in these situations) which allowed the drafter to have an accurate right angle at any point on the page quite quickly. These machines oftentimes included the power to alter the bending, thereby removing the need for the triangles likewise.

In addition to the mastery of the mechanics of cartoon lines, arcs and circles (and text) onto a piece of paper—with respect to the detailing of physical objects—the drafting try requires a thorough understanding of geometry, trigonometry and spatial comprehension, and in all cases demands precision and accuracy, and attention to detail of high order.

Although drafting is sometimes accomplished by a projection engineer, builder, or shop personnel (such as a machinist), skilled drafters (and/or designers) usually accomplish the task, and are always in demand to some degree.

Computer aided design [edit]

Today, the mechanics of the drafting task have largely been automated and accelerated through the use of reckoner-aided design systems (CAD).

In that location are two types of computer-aided design systems used for the production of technical drawings: two dimensions ("2D") and three dimensions ("3D").

An example of a drawing drafted in AutoCAD

2d CAD systems such as AutoCAD or MicroStation replace the paper cartoon discipline. The lines, circles, arcs, and curves are created within the software. Information technology is down to the technical drawing skill of the user to produce the cartoon. There is still much scope for error in the cartoon when producing first and third angle orthographic projections, auxiliary projections and cantankerous-section views. A 2nd CAD system is merely an electronic drawing lath. Its greatest forcefulness over direct to newspaper technical drawing is in the making of revisions. Whereas in a conventional manus drawn technical drawing, if a mistake is establish, or a modification is required, a new drawing must be made from scratch, the 2d CAD system allows a re-create of the original to be modified, saving considerable time. 2D CAD systems can be used to create plans for large projects such as buildings and aircraft simply provide no style to cheque the diverse components will fit together.

A 3D CAD system (such as KeyCreator, Autodesk Inventor, or SolidWorks) first produces the geometry of the part; the technical drawing comes from user divers views of that geometry. Whatsoever orthographic, projected or sectioned view is created by the software. There is no telescopic for error in the production of these views. The main telescopic for error comes in setting the parameter of starting time or third angle projection and displaying the relevant symbol on the technical drawing. 3D CAD allows individual parts to be assembled together to stand for the final product. Buildings, shipping, ships, and cars are modeled, assembled, and checked in 3D before technical drawings are released for manufacture.

Both 2d and 3D CAD systems can be used to produce technical drawings for any discipline. The various disciplines (electrical, electronic, pneumatic, hydraulic, etc.) have industry recognized symbols to stand for common components.

BS and ISO produce standards to show recommended practices but it is up to individuals to produce the drawings to a standard. There is no definitive standard for layout or style. The only standard across engineering workshop drawings is in the creation of orthographic projections and cross-section views.

In representing circuitous, three-dimensional objects in two-dimensional drawings, the objects can be described by at least one view plus material thickness notation, two, 3 or every bit many views and sections that are required to show all features of object.

Applications [edit]

Architecture [edit]

To program a renovation, this architect takes measurements which he will later enter into his calculator-aided design system.

The art and design that goes into making buildings is known every bit architecture. To communicate all aspects of the shape or pattern, detail drawings are used. In this field, the term plan is often used when referring to the total section view of these drawings as viewed from three anxiety to a higher place finished floor to testify the locations of doorways, windows, stairwells, etc.[4] Architectural drawings describe and document an builder'southward design.[five]

Engineering science [edit]

Engineering tin be a very broad term. It stems from the Latin ingenerare, significant "to create".[6] Because this could apply to everything that humans create, it is given a narrower definition in the context of technical drawing. Engineering drawings by and large deal with mechanical engineered items, such as manufactured parts and equipment.

Engineering science drawings are usually created in accordance with standardized conventions for layout, nomenclature, estimation, appearance (such as typefaces and line styles), size, etc.

Its purpose is to accurately and unambiguously capture all the geometric features of a product or a component. The finish goal of an engineering science drawing is to convey all the required data that will permit a manufacturer to produce that component.

Software engineering [edit]

Software applied science practictioners make use of diagrams for designing software. Formal standards and modeling languages such as Unified Modeling Language (UML) exist simply most diagramming happens using breezy ad hoc diagrams that illustrate a conceptual model.[7]

Practitioners reported that diagramming helped with analysing requirements,[vii] : 539 design, refactoring, documentation, onboarding, communication with stake holders.[8] : 560 Diagrams are often transient or redrawn every bit required. Redrawn diagrams can acts as a course of shared understanding in a squad.[eight] : 561

[edit]

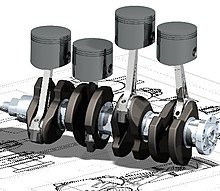

Technical illustration [edit]

Technical illustration is the use of illustration to visually communicate information of a technical nature. Technical illustrations can be component technical drawings or diagrams. The aim of technical illustration is "to generate expressive images that effectively convey certain data via the visual channel to the man observer".[9]

The principal purpose of technical illustration is to describe or explain these items to a more or less nontechnical audience. The visual image should exist accurate in terms of dimensions and proportions, and should provide "an overall impression of what an object is or does, to enhance the viewer's involvement and agreement".[10]

According to Viola (2005), "illustrative techniques are frequently designed in a style that even a person with no technical agreement conspicuously understands the piece of art. The use of varying line widths to emphasize mass, proximity, and scale helped to make a unproblematic line drawing more understandable to the lay person. Cross hatching, stippling, and other low abstraction techniques gave greater depth and dimension to the subject matter".[9]

Cutaway drawing [edit]

A cutaway drawing is a technical analogy, in which role of the surface of a three-dimensional model is removed in order to testify some of the model's interior in relation to its exterior.

The purpose of a cutaway drawing is to "allow the viewer to have a look into an otherwise solid opaque object. Instead of letting the inner object shine through the surrounding surface, parts of outside object are just removed. This produces a visual appearance as if someone had cutout a piece of the object or sliced it into parts. Cutaway illustrations avoid ambiguities with respect to spatial ordering, provide a sharp contrast between foreground and background objects, and facilitate a good understanding of spatial ordering".[xi]

Technical drawings [edit]

Types [edit]

The 2 types of technical drawings are based on graphical projection.[one] This is used to create an image of a three-dimensional object onto a two-dimensional surface.

Two-dimensional representation [edit]

2-dimensional representation uses orthographic projection to create an paradigm where only ii of the three dimensions of the object are seen.

Three-dimensional representation [edit]

In a three-dimensional representation, likewise referred to as a pictorial, all iii dimensions of an object are visible.

Views [edit]

Multiview [edit]

Multiview is a type of orthographic project. There are ii conventions for using multiview, first-angle and 3rd-bending. In both cases, the front or main side of the object is the same. Showtime-bending is drawing the object sides based on where they land. Example, looking at the front end side, rotate the object 90 degrees to the right. What is seen will exist drawn to the right of the front end side. Third-bending is drawing the object sides based on where they are. Case, looking at the front side, rotate the object 90 degrees to the right. What is seen is actually the left side of the object and will be drawn to the left of the front side.

Section [edit]

While multiview relates to external surfaces of an object, section views show an imaginary airplane cutting through an object. This is often useful to show voids in an object.

Auxiliary [edit]

Auxiliary views utilize an additional projection plane other than the common planes in a multiview. Since the features of an object need to show the true shape and size of the object, the projection airplane must be parallel to the object surface. Therefore, any surface that is non in line with the 3 major centrality needs its ain projection plane to show the features correctly.

Pattern [edit]

Patterns, sometimes called developments, bear witness the size and shape of a flat slice of material needed for afterward bending or folding into a three-dimensional shape.[12]

Exploded [edit]

An exploded-view drawing is a technical drawing of an object that shows the human relationship or order of assembly of the various parts.[13] It shows the components of an object slightly separated by distance or suspended in surrounding infinite in the instance of a three-dimensional exploded diagram. An object is represented equally if there had been a small controlled explosion emanating from the centre of the object, causing the object's parts to be separated relative distances away from their original locations.

An exploded view drawing (EVD) can testify the intended assembly of mechanical or other parts. In mechanical systems, the component closest to the eye is usually assembled offset or is the chief part within which the other parts are assembled. The EVD tin also help to correspond the disassembly of parts, where those on the outside are normally removed showtime.[14]

Standards and conventions [edit]

Basic drafting paper sizes [edit]

There have been many standard sizes of paper at different times and in different countries, simply today most of the globe uses the international standard (A4 and its siblings). Due north America uses its own sizes.

-

ISO "A serial" newspaper sizes used in about countries of the earth

-

ANSI paper sizes used in North America

Patent cartoon [edit]

The applicant for a patent volition exist required by constabulary to furnish a drawing of the invention if or when the nature of the instance requires a cartoon to empathise the invention with the job. This drawing must be filed with the application. This includes practically all inventions except compositions of thing or processes, but a drawing may as well be useful in the instance of many processes.[thirteen]

The cartoon must bear witness every feature of the invention specified in the claims and is required by the patent office rules to be in a detail course. The Office specifies the size of the sheet on which the drawing is made, the blazon of paper, the margins, and other details relating to the making of the drawing. The reason for specifying the standards in detail is that the drawings are printed and published in a uniform mode when the patent issues and the drawings must also be such that they tin be readily understood by persons using the patent descriptions.[xiii]

Sets of technical drawings [edit]

Working drawings for product [edit]

Working drawings are the set up of technical drawings used during the manufacturing phase of a product.[15] In architecture, these include civil drawings, architectural drawings, structural drawings, mechanical systems drawings, electrical drawings, and plumbing drawings.

Associates drawings [edit]

Assembly drawings show how unlike parts go together, identify those parts by number, and accept a parts listing, oftentimes referred to every bit a pecker of materials.[16] In a technical service manual, this type of drawing may exist referred to equally an exploded view drawing or diagram. These parts may be used in engineering science.

As-fitted drawings [edit]

Also called Every bit-Built drawings or As-made drawings. As-fitted drawings stand for a record of the completed works, literally 'as fitted'. These are based upon the working drawings and updated to reflect any changes or alterations undertaken during structure or industry.[17]

See also [edit]

- Circuit diagram

- Linear scale

- Reprography

- Schematic diagram

- Shop drawing

- Technical advice

- Technical lettering

- Specification (technical standard)

References [edit]

- ^ a b Goetsch, David 50.; Chalk, William S.; Nelson, John A. (2000). Technical Drawing. Delmar Technical Graphics Series (4th ed.). Albany: Delmar Learning. p. iii. ISBN978-0-7668-0531-6. OCLC 39756434.

- ^ a b Richard Boland and Fred Collopy (2004). Managing as designing. Stanford Academy Printing, 2004. ISBN 0-8047-4674-5, p.69.

- ^ Bhatt, North.D. Machine Cartoon. Charotar Publication.

- ^ Jefferis, Alan; Madsen, David (2005), Architectural Drafting and Pattern (5th ed.), Clifton Park, NY: Delmar Cengage Learning, ISBN 1-4018-6715-4

- ^ Goetsch et al. (2000) p. 792

- ^ Lieu, Dennis K; Sorby, Sheryl (2009), Visualization, Modeling, and Graphics for Engineering Design (1st ed.), Clifton Park, NY: Delmar Cengage Learning, ISBN 978-1-4018-4249-9, pp. 1–2

- ^ a b Baltes, Sebastian; Diehl, Stephan (11 Nov 2014). "Sketches and diagrams in practise". Proceedings of the 22nd ACM SIGSOFT International Symposium on Foundations of Software Engineering science. FSE 2014. Hong Kong, Cathay: Association for Computing Machinery: 530–541. arXiv:1706.09172. doi:10.1145/2635868.2635891. ISBN978-1-4503-3056-5.

- ^ a b Cherubini, Mauro; Venolia, Gina; DeLine, Rob; Ko, Amy J. (29 April 2007), "Let's go to the whiteboard: how and why software developers use drawings", Proceedings of the SIGCHI Conference on Homo Factors in Computing Systems, New York, NY, USA: Association for Computing Machinery, pp. 557–566, doi:10.1145/1240624.1240714, ISBN978-one-59593-593-9 , retrieved 8 September 2021

- ^ a b Ivan Viola and Meister E. Gröller (2005). "Smart Visibility in Visualization". In: Computational Aesthetics in Graphics, Visualization and Imaging. L. Neumann et al. (Ed.)

- ^ "The Role of the Technical Illustrator in Manufacture". industriegrafik.com. 15 June 2002. Archived from the original on 14 August 2009. Retrieved 15 February 2009.

- ^ Diepstraten, J.; Weiskopf, D.; Ertl, T. (2003). "Interactive Cutaway Illustrations" (PDF). vis.uni-stuttgart.de. Archived from the original (PDF) on 16 December 2005. in Brunet, P.; Fellner, D. (eds.). "Eurographics 2003". Eurographics. The Eurographics Association and Blackwell Publishers. 22 (iii).

- ^ Goetsch et al. (2000), p. 341

- ^ a b c "General Information Concerning Patents § one.84 Standards for drawings". USPTO.gov. Jan 2005. Archived from the original on 30 January 2009. Retrieved 13 February 2009.

- ^ Michael Eastward. Brumbach, Jeffrey A. Clade (2003). Industrial Maintenance. Cengage Learning, 2003 ISBN 0-7668-2695-iii, p.65

- ^ Ralph Westward. Liebing (1999). Architectural working drawings. John Wiley and Sons, 1999. ISBN 0-471-34876-7.

- ^ Goetsch et al. (2000), p. 613

- ^ "as-built drawings". BusinessDictionary.com. 26 December 2017. Archived from the original on iii Dec 2017. Retrieved one January 2018.

Further reading [edit]

- Peter J. Booker (1963). A History of Engineering Cartoon. London: Northgate.

- Franz Maria Feldhaus (1963). The History of Technical Drawing

- Wolfgang Lefèvre ed. (2004). Picturing Machines 1400–1700: How technical drawings shaped early engineering do. MIT Press, 2004. ISBN 0-262-12269-3

External links [edit]

- Historical technical diagrams and drawings at NASA.

- A history of CAD

- Drafting Standards

Source: https://en.wikipedia.org/wiki/Technical_drawing